matters needing attention

explain:

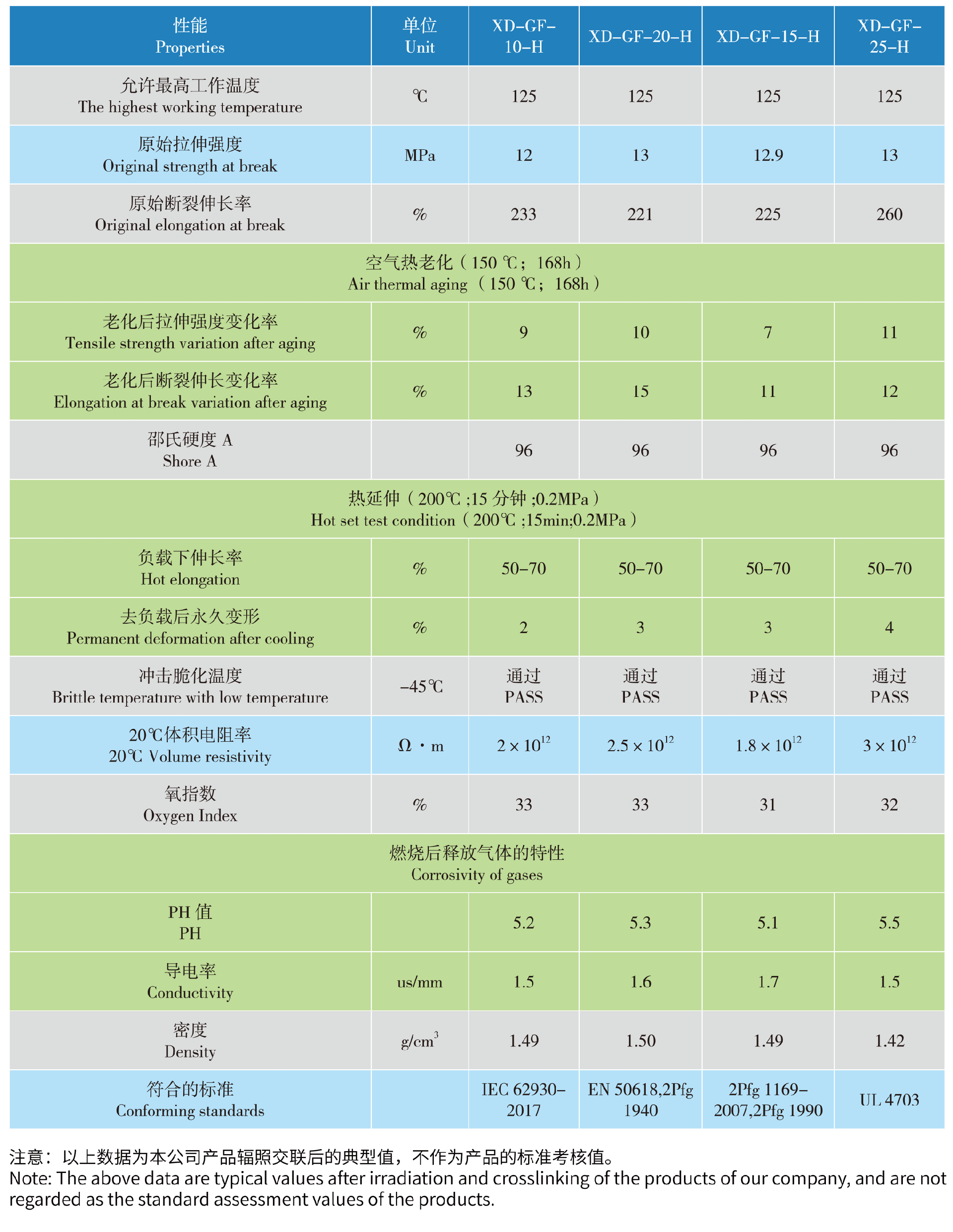

This product has excellent mechanical properties, electrical properties and flame retardancy. It is a cable material for photovoltaic cable sheath.

squeeze:

It is recommended that this series of halogen-free low smoke resistance fuels be dried for about 2 hours before extrusion. The drying temperature is 70 ℃. The drying temperature can rise * 80 ℃ when the machine is started. It is recommended to use a screw with a length diameter ratio of about 25 and good plasticization for processing. The extrusion temperature is 120 ℃ - 125 ℃ - 130 ℃ - 135 ℃ - 140 ℃ - 145 ℃ (reference temperature).

packing:

Net weight: 25kg: inner aluminum foil/polyethylene composite film bag, outer kraft paper composite bag.

Net weight 1000kg: inner aluminum foil/polyethylene composite film bag, outer polypropylene woven composite bag.

Storage:

The product shall be stored in a clean, dry and ventilated warehouse, and shall not be damaged by abnormal conditions such as sunshine, rain and water immersion. The storage temperature shall not be lower than 0 ℃. The storage period of the product shall not exceed 6 months from the date of production.