MATTERS NEEDING ATTENTION

Description:

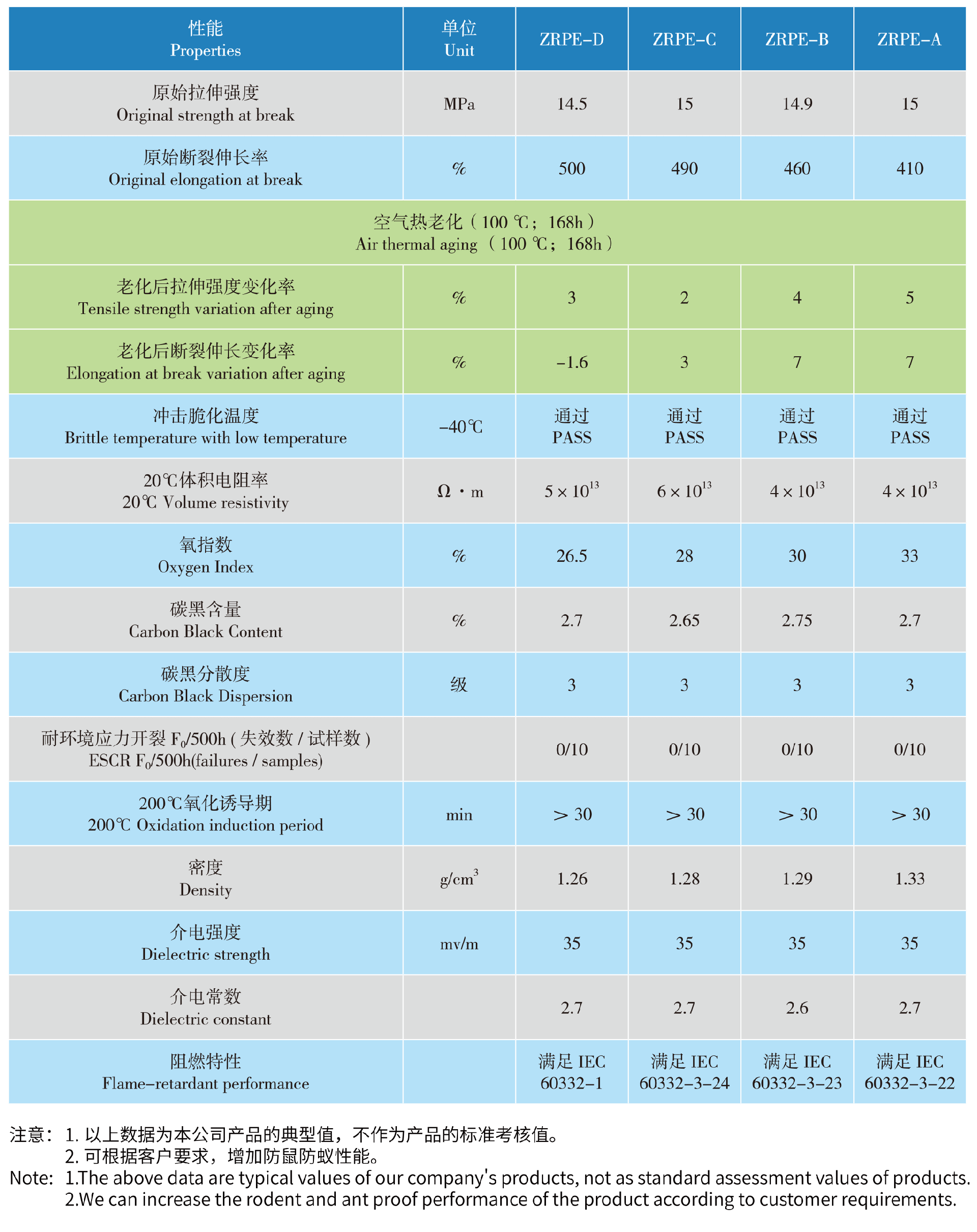

This series of products are suitable for medium and low voltage cables used in rail transit and crowded places. On the basis of GB/T15065-2009 performance, the product has added flame retardant performance, optimized anti-cracking performance as cable sheath , and met the flame retardant requirements.

Processing:

This series of products,it is recommended to dry for about 2 hours before processing, drying temperature: 70℃, drying temperature can rise to 80℃ in the starting state. We recommend using PVC double thread screw for machining processing. The processing temperature is suggested to be :135℃-140℃-145℃-150℃-155℃-160℃-165℃-170℃.(reference temperature)Tips: The temperature of the machine head area is not too low to prevent cracking of the joint glue.

Packing:

Net weight 25kg: Inner aluminum foil/polyethylene composite film bag, outer kraft paper composite bag.

Net weight 1000kg: Inner aluminum foil/polyethylene composite film bag, outer polypropylene woven composite bag.

Storage:

The product should be stored in a clean, dry and ventilated warehouse, and should not be damaged by sun, rain, water and other abnormal conditions. Storage temperature should not be lower than 0℃. The storage period of the product shall not exceed 6 months from the date of production.