MATTERS NEEDING ATTENTION

Description:

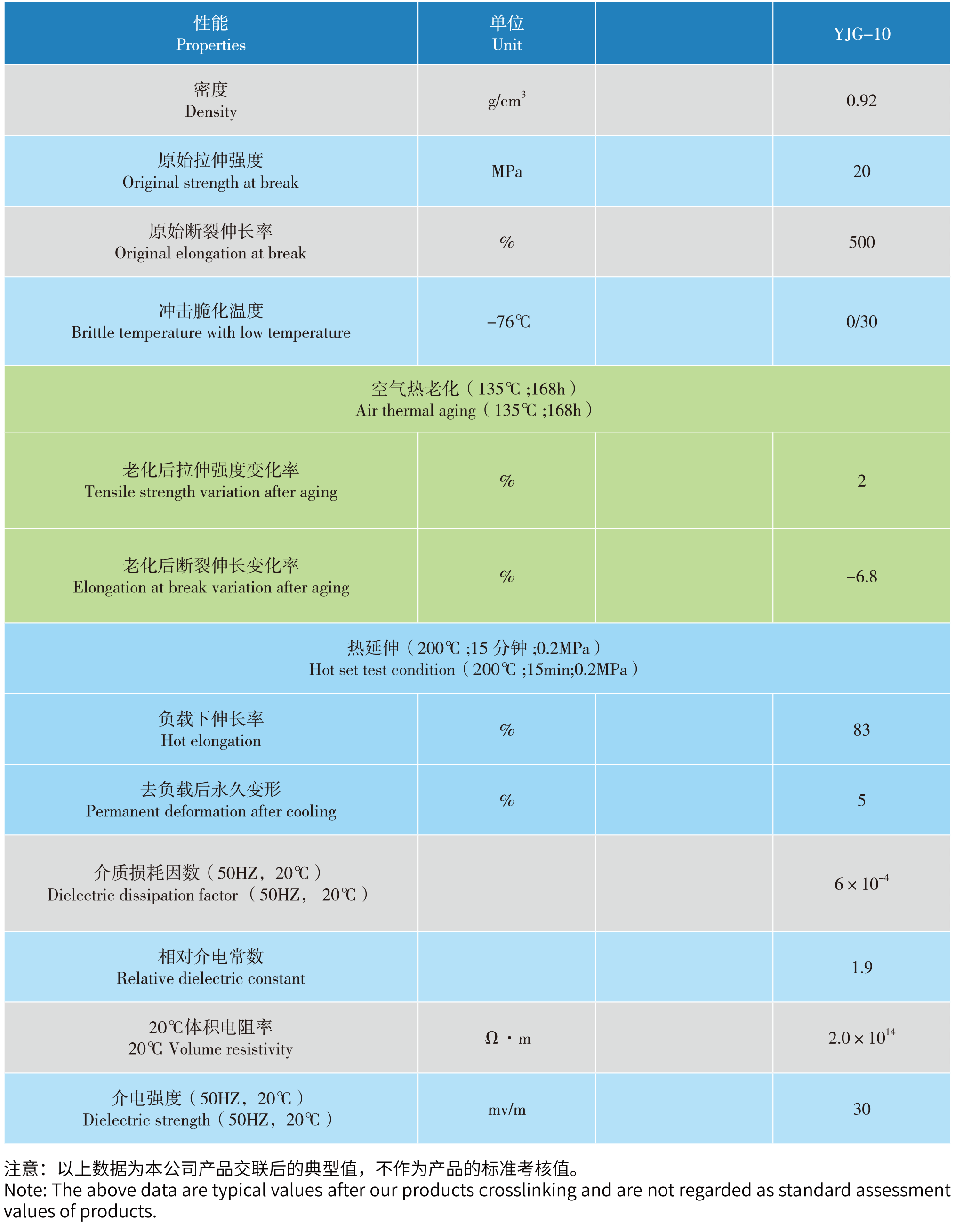

Silane crosslinked polyethylene (XLPE) insulation material not only has high insulation resistance, voltage strength and excellent dielectric properties, copper oxidation resistance, environmental stress cracking and heat resistance, but also has good physical and mechanical properties, such as tensile resistance, bending resistance, torsion resistance and so on. The material completely replaces POLYvinyl chloride. The cable made of this material has the following advantages: 1. The maximum working temperature allowed is 90℃; 2. In case of short circuit, the maximum allowable temperature is 250℃; 3. In case of emergency, the maximum allowed temperature is 130℃.

Processing:

Most single screw extruders that process thermoplastics can process this product. The screw compression ratio is generally 2.5-3, the aspect ratio is about 25, and the screw is the common type with equal distance and unequal depth. The processing reference temperature is 150℃-180℃-190℃-200℃-210℃-220℃. The cooling water temperature is recommended to adopt step-by-step cooling to reduce the internal stress of insulating material.

Packing:

Net weight 25kg: Inner aluminum foil/polyethylene composite film bag, outer kraft paper composite bag,divided into A, B bags.

Bag A :Material A with 23.75 kg

Bag B :Material B with 1.25 kg

Storage:

The product should be stored in a clean, dry and ventilated warehouse, and should not be damaged by sun, rain, water and other abnormal conditions. Storage temperature should not be lower than 0℃. The storage period of the product shall not exceed 6 months from the date of production.